I-Laser ekroliweyo, ukucoca, i-welding kunye noomatshini bokumakisha

Fumana isicatshulwa

Iimveliso

umatshini wokumakisha i-laser yeplastiki

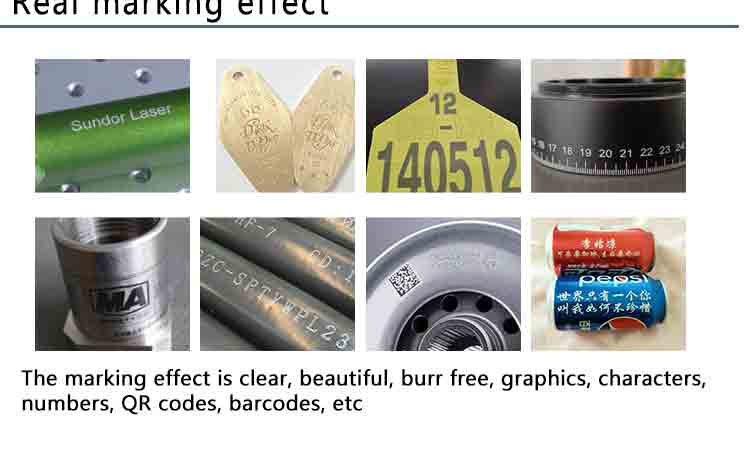

Ukumakishwa kwe-laser kuye kwaba yitekhnoloji ebalulekileyo kwishishini leplastiki njengoko libonelela ngendlela efanelekileyo nechanekileyo yokumakisha iintlobo ezahlukeneyo zeplastiki. Oomatshini bokumakisha base-leser ye-laser ye-leser basebenzisa i-laser ephezulu ye-leser ye-leser yokwakha kunye nokuyila kwe-etke okanye oonobumba kumphezulu wezixhobo zeplastiki.

Esona sibonelelo siphambili sokusebenzisa iumatshini wokumakisha i-laser kwiplastikiInqanaba lokuchaneka libonelela. Le teknoloji inokwenza amanqaku aneenkcukacha kwaye achanileyo, ebaluleke kakhulu kumashishini anjengezixhobo zonyango, apho kufuneka ilebheli echanekileyo ukuze kuthotyelwe.

Kwaye, ukumakishwa kwe-laser kuyasisigxina kwaye akuyi kuphelelwa okanyemarkiplastikiiindawo eziphezulu. Oku kwenza ukuba kulungele iimveliso eziza kusetyenziswa kwiindawo ezinobunkunkqele okanye ezivezwe.

Enye inzuzo ephambili yeI-Laser Mark kwiPlastikiskukufezekisa umatshini, onokuthi usetyenziswe kwizinto ezahlukeneyo, kubandakanya i-polypropylene, i-polythylene, polycarbonate, nangaphezulu. Oku kubaluleke kakhulu kubavelisi abasebenza ngeendlela ezahlukeneyo zezakhiwo zeplastiki, njengoko ibavumela ukuba basebenzise umatshini omnye kwizicelo ezininzi, ukugcina ixesha kunye nemali.

Ukongeza, zininzi iintlobo zeOomatshini bokumakisha i-laser yeplastiki, kubandakanya i-CO2 i-Coo2 kunye ne-fiber labers, enika amanqanaba ahlukeneyo amandla kunye nokuchaneka. Ii-coors ze-CO2 zilungele ukumakisha phantse zonke iintlobo zeplastiki kwaye zibonelela ngesantya sokumakisha ngokukhawuleza. Ngokwahlukileyo, i-fiber lairs ilungele ukumakisha okuphezulu, ukubonelela ngamanqaku achanekileyo kunye namanqaku ahlaziyiweyo.

Ekugqibeleni, ukumakishwa kwe-laser yinkqubo enobuhlobo bendalo njengoko kungabandakanyi ukusetyenziswa kwee-inki okanye iichemicals ezinokulimaza indalo. Umatshini usebenza ngokuphuma komphezulu weplasitiki, ukudala i-steam enokuthi ishiye imakishi oyifunayo.

ubuso, ukudala i-steam enokuthi ishiye imakishi oyifunayo.