I-Laser ekroliweyo, ukucoca, i-welding kunye noomatshini bokumakisha

Fumana isicatshulwa

Iimveliso

I-PVC ye-PVC ye-PVC yokumakisha

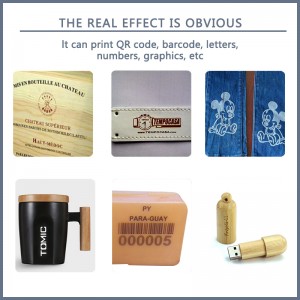

Umbhobho we-PVC uhlala esetyenziswa kwimizi-mveliso eyahlukeneyo kubandakanya ukwenza imibhobho, uzokwakha, kunye nokunkcenkceshela. Ukuqinisekisa ukuba le mibhobho iyaziwa ngokulula kwaye inkcazo yabo icinyiwe, isetyenzisiwe iMarking. I-PVC Pipe Pipe Laser Comman Comarks ibonelela ngendlela efanelekileyo yokudala amanqaku asisigxina kumbhobho we-PVC.

I-PVC ye-PVC ye-PVC ye-Laser Laser isebenzisa i-laser ye-leser yokukhupha umbhobho wePVC. Le nkqubo idala uphawu olusisigxina olungayi kuphelisa, i-peel okanye icime. Amanqaku anokuba ngohlobo lwesicatshulwa, amanani, iilogo, okanye nawuphi na olunye uyilo olucelwe nguMvelisi.

Esona sibonelelo siphambili sokusebenzisa i-PVC Pipe Shour Surar sisimo sophawu. Umanqaku wenziwe ngokutshintsha umaleko womphezulu wombhobho we-PVC ukuze ungayi kuqhubela phambili okanye ukupheliswa nangaphantsi kweemeko zokusingqongileyo. Oku kuqinisekisa ukuba imigaqo-nkqubo ye-Pipe inokulandelwa ngokulula, ngakumbi kwizicelo apho ulondolozo kunye nokulungiswa kuyafuneka kubo bonke ubomi bombhobho.

Elinye imvume yokusebenzisa umatshini wokumakisha i-PVC ye-PVC kukuchaneka kunye nokungqinelana kwamanqaku avelisiweyo. Umatshini usebenzisa isoftware enobuchule ukudala amanqaku acocekileyo kunye neyunifomu ngokuchaneka okuphezulu. Oku kuthetha ukuba abamakishi banokubekwa ecaleni kwaye balungelelaniswa, baqinisekise ukuba kulula ukufunda nokuqinisekisa ukulandelela ngokupheleleyo kombhobho.

Ukongeza, oomatshini bokumakisha base-PVC bagcina abavelisi bemveliso kunye nemali. Sebenzisa iindlela zemveli zemveli, ukudala ii-tags kunokuthatha ixesha kwaye kuyabiza. Ngokusebenzisa umatshini wokumakisha i-PVC ye-PVC, inkqubo yokumakisha ikhawuleza, isebenze kwaye iguquguquka. Ingaphawula inani elikhulu lemibhobho kwixesha elifutshane, okanye linokulungiswa ukuze kwenziwe ngokumakisha ngokweemfuno zabathengi.

Ukongeza, umatshini wokumakisha i-PVC Laser ye-Laser yindawo enobuhlobo. Itekhnoloji esetyenzisiweyo ngumatshini yenzelwe ukunciphisa ifuthe kwindalo esingqongileyo njengoko ingabandakanyi ukusetyenziswa kwazo naziphi na iikhemikhali okanye izinyibilikisi. Inkqubo yokumakisha iphunyezwa kusetyenziswa i-mayithi elawulwa ngumatshini, ukunciphisa isixa senkunkuma eyenziwe ngexesha lenkqubo yokumakisha.

Okokugqibela, ukusetyenziswa koomatshini wokumakisha i-PVC ye-PVC ye-Laser Ukuqinisekisa ukuthotyelwa. Umbhobho we-PVC osetyenziswa kumashishini ahlukeneyo anemigangatho ethile ekufuneka ilandelwe malunga nokumakisha kunye nokulandelela. Isisombululo sezi mfuno sinikezelwa ngokusebenzisa umatshini wokumakisha i-PVC ye-PVC, enokuthi ngokulula kwaye ngokuchanekileyo imibhobho yePVC.

Ukuphelisa, oomatshini bokumakisha be-PVC babalulekile kumashishini ahlukeneyo apho kusetyenziswa imibhobho yePVC. Babonelela ngendlela efanelekileyo nenoqoqosho, inoqoqosho kunye nendawo yokudala amanqaku esigxina kumbhobho we-PVC. Ngokusebenzisa isoftware enobuchule kunye ne-laser elawulwa yi-laser elawulwayo, ukumakisha ngokukhawuleza, ngokuchanekileyo nangokuguquguqukayo, ukuqinisekisa ukulandelela kunye nokuthobela.

Ukuqukumbela, umzi-mveliso womatshini wokumakisha unenzuzo ezininzi, kubandakanya inkqubo yoqinisekiso lomgangatho, ukusebenza kweendleko, ukuzuza kwexabiso, inkxaso yemveliso, inkxaso entsha kunye nenkxaso yentengiso kunye nenkxaso yasemva kokuthengisa. Ezi zinto ziluncedo, zidityaniswa nabasebenzi abanobuchule, itekhnoloji ephambili kunye neenkqubo ezenziwe lula, ziqinisekise ukuba umzi-mveliso wokumakisha uvelisa oomatshini bokumakisha kwaye bagqithise iimfuno zomthengi kunye neenkcazo.